Interview with Bluways

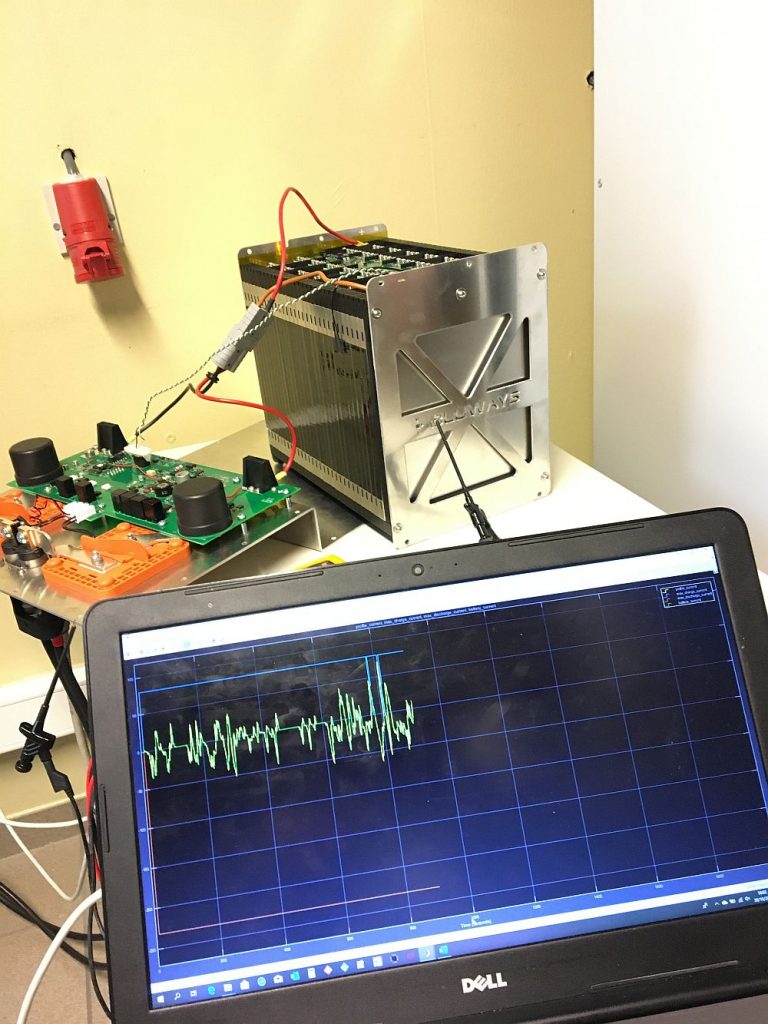

The first piece of hardware in the PANDA project is ready. Johan Lecoutere from Bluways: “It is a battery for an electrical car, specifically designed to handle large currents”. The prototype will be delivered to the researchers at the Vrije Universiteit Brussel, who will use it to build and validate their battery models.

The prototype contains quite a few novelties. Lecoutere: “Nowadays electrical cars have large e-motors, that draw large currents, easily a few hundred Amperes. In the project we don’t want our models to fail because the batteries are limited in the current they can supply. So we had to make sure the hardware can deliver.” Bluways developed dedicated connections between the cells and the supporting wiring. Lecoutere: “These so-called bus bars are key to delivering the currents, and we re-designed them completely.” And there are innovations to make the battery more robust. Lecoutere: “In all of the connections to our battery management system we avoided the use of wires. Wires easily suffer from the vibrations that are typical in a moving car, and our fixed connections are more reliable.” The communication between cells and controller (to monitor e.g. the cell temperature) is current-driven rather than voltage-driven. “Failures are typically caused by distrubances in voltage-driven signals. By using a current-driven bus we can make a very reliable connection.” And finally, all electronic signals are picked up using mechanical screw connections. Lecoutere, smiling as he says: “We are proud of what we have built, and the design details are proprietary knowledge. And of course the module meets all UNECE-100-R2 regulations.”

Bluways has characterised the behaviour of the battery. The measurement results (load, temperature, voltage, current) have been shared with the Vrije Universiteit Brussel, to serve as a basis for their MatLab and Amesim models. The battery will be sent to Brussels for further validation.

Johan Lecoutere, CEO, Bluways