Interview with VALEO

Black-box models: confidential and flexible at the same time

“The black-box models in PANDA work very well for us,” says Aurélien Lievre, system team leader at Valeo. “At Valeo we focus on the e-machine and the inverter. A lot of our knowledge is confidential, specifically on our 48 V machine. Even though we cannot share all our knowledge, we still want to develop and test our products with customers or other engineers. In PANDA we can keep our knowledge confidential, while being completely flexible with our models.”

In the conventional approach, engineers use two types of models when they develop electrical systems, typically in Matlab Simulink software. On the one hand, the physical models describe the behaviour of the electrical components, such as the currents in the e-motor, or the heating in the inverter. On the other hand, the control models describe the behaviour of the sensors and the controller. “Just the physical aspect is not enough,” says Lievre, “the controller has to be included if you want to model the whole system.” Problems occur when the models become too complicated. “The whole simulation becomes time consuming. So, we need to manage the complexity of the models: use simple models in some cases, and more complex models in other cases.”

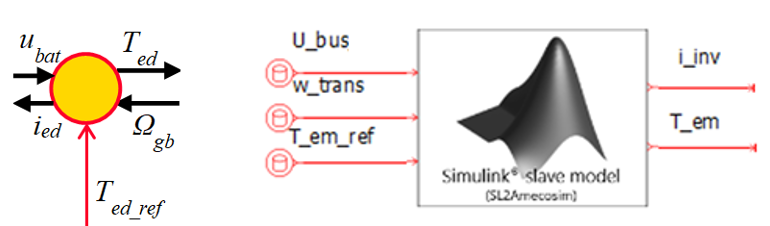

The PANDA approach uses the energetic macroscopic representation formalism (EMR), which makes it easy to interface different types of models by standardizing the inputs and the outputs. “At each level we can link the different types of physical values.” On a component level, we look at the current in the e-machine to get the right torque. But at a vehicle level, you only see the speed or acceleration of the vehicle.” In PANDA these levels can be easily linked to build the control system. “At each level EMR is a good way to build this control.”

“We use the black-box models, because we can keep all our equations confidential, and we can hide all the parameters and all the data.” The only data that needs to be shared, are the inputs and the outputs of the model. “For the e-machine model the accessible inputs are the torque request, the speed of the e-machine, DC voltage and the ambient temperature. The model computes the outputs, which are the torque that the machine delivers, the DC current and self-heating (temperatures of some components of the e-machine).”

In the PANDA project, Siemens has integrated the EMR methods in their modeling platform Simcenter Amesim. “If customers want to use the EMR approach, Siemens has written tutorials on how to compute the Amesim black-box models from Matlab Simulink models.”

Figure: EMR of the e-drive and it’s corresponding Simcenter AMESim blackbox model

Multi-level behaviour models of e-drives [VEEM – May 2020]

This report provided different models of electric drives based on a blackbox approach and machine lerarning, and the model organization according to the PANDA methodology.